Immediate loading of post-extraction implant in a high-esthetic value area: digital workflow advantages.

A clinical case report by Vincenzo Santomauro, Italy

The use of the latest digital workflows in both surgery and prosthetics is introducing significant innovations, especially concerning ways of making the clinical procedures easier and faster.

Nowadays, using the Straumann® Virtuo Vivo™ intraoral scanner and the coDiagnostiX® Dental Wings software, it is possible to create a digital workflow which, starting with the cone beam x-ray examination, followed by surgical-prosthetic digital planning, allows us to facilitate immediate loading of a temporary prosthesis.

This is also possible thanks to the CAD Straumann CARES® Visual software, which works in harmony with coDiagnostiX®.

The aim of this article is to highlight how, by implementing a clinical and prosthetic digital workflow, it is possible to quickly simplify these procedures and guarantee highly-precise and predictable results.

Initial situation

A systematically healthy 50-year-old man presented at our practice requesting the restoration of a missing crown in a central incisor. His main priority was the esthetic appearance, and his expectations were high.

The extraoral and intraoral examination revealed a medium/high smile line, medium-thickness gingival biotype, good general oral hygiene and multiple gingival recessions. Furthermore, he presented a horizontal fracture below the cemento-enamel junction on tooth #11 with the exposure of the root canal and plaque accumulation in the area (Fig. 1).

The periapical x-ray and CBCT examination showed images compatible with interproximal bone loss and partial root canal treatment (Fig. 2).

Taking into consideration the patient’s expectations and the clinical and radiographic findings, the placement of a post-extraction dental implant was planned.

Treatment planning

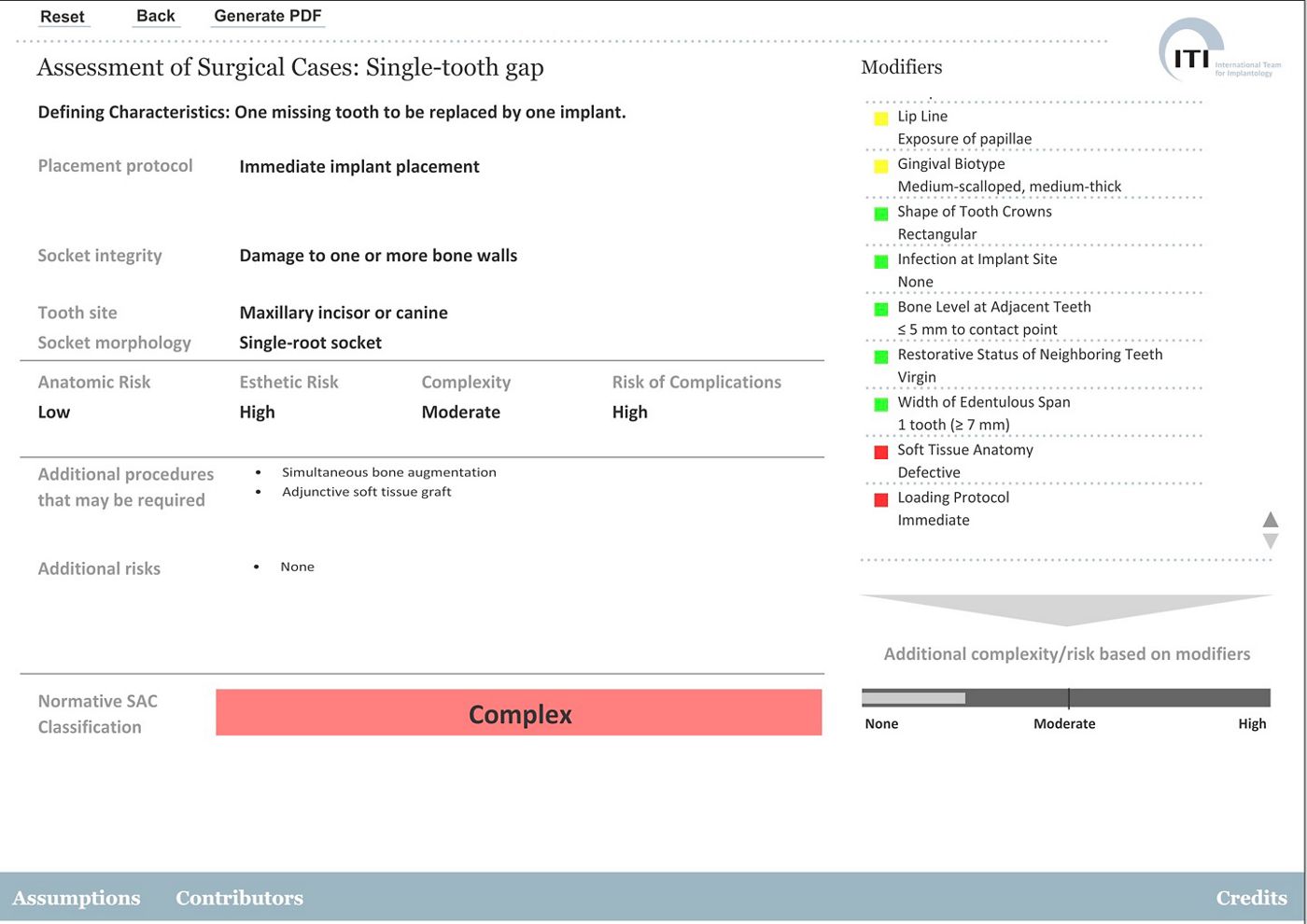

The SAC assessment tool was used to assess the complexity and potential risk associated with this case. Since the protocol used included immediate loading and other modifiers, this case was defined as advanced and complex (Fig. 3).

The treatment plan included the insertion of one Straumann® BLX Roxolid® SLActive® post-extraction implant using computer-guided flapless surgery and a screwed, immediately-loaded temporary crown in order to minimize the patient’s esthetic discomfort and enable immediate soft-tissue conditioning.

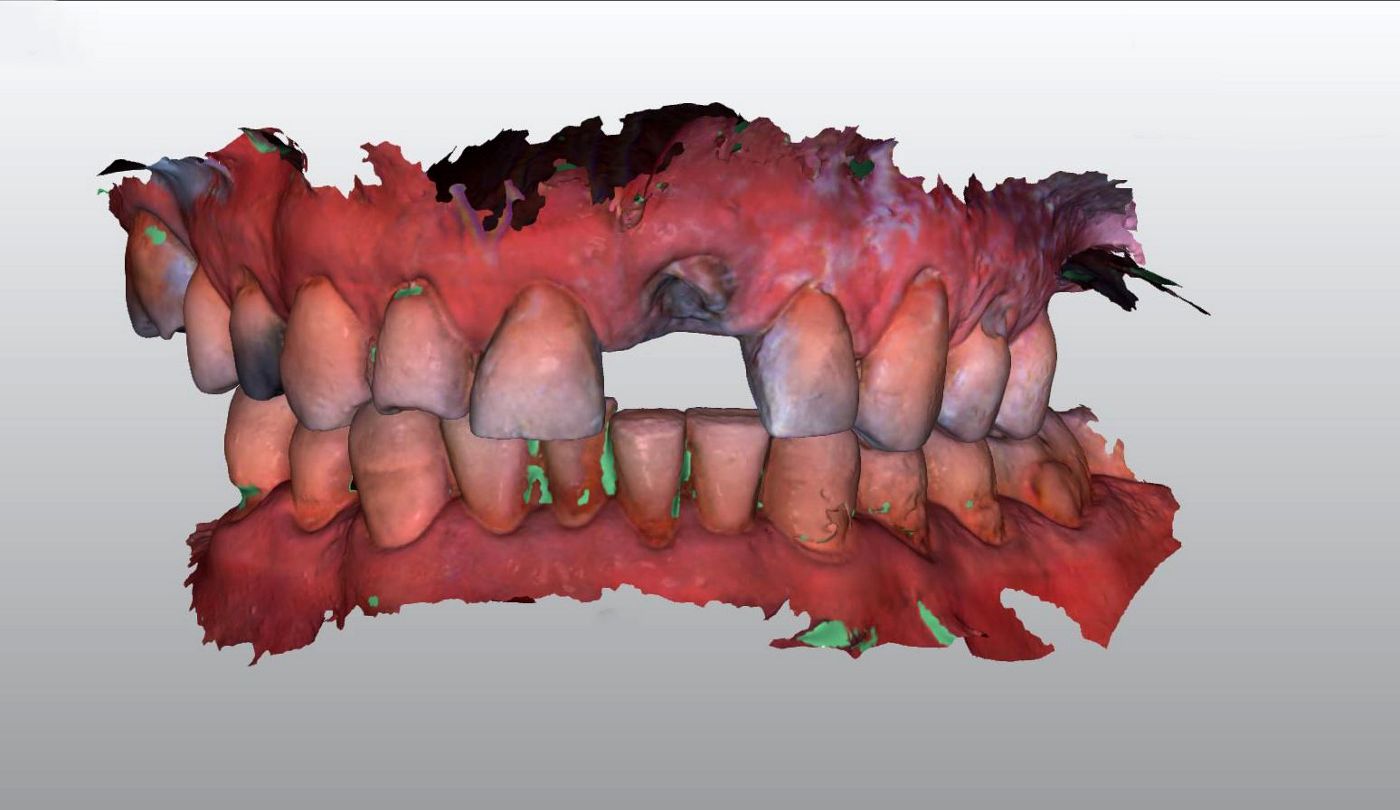

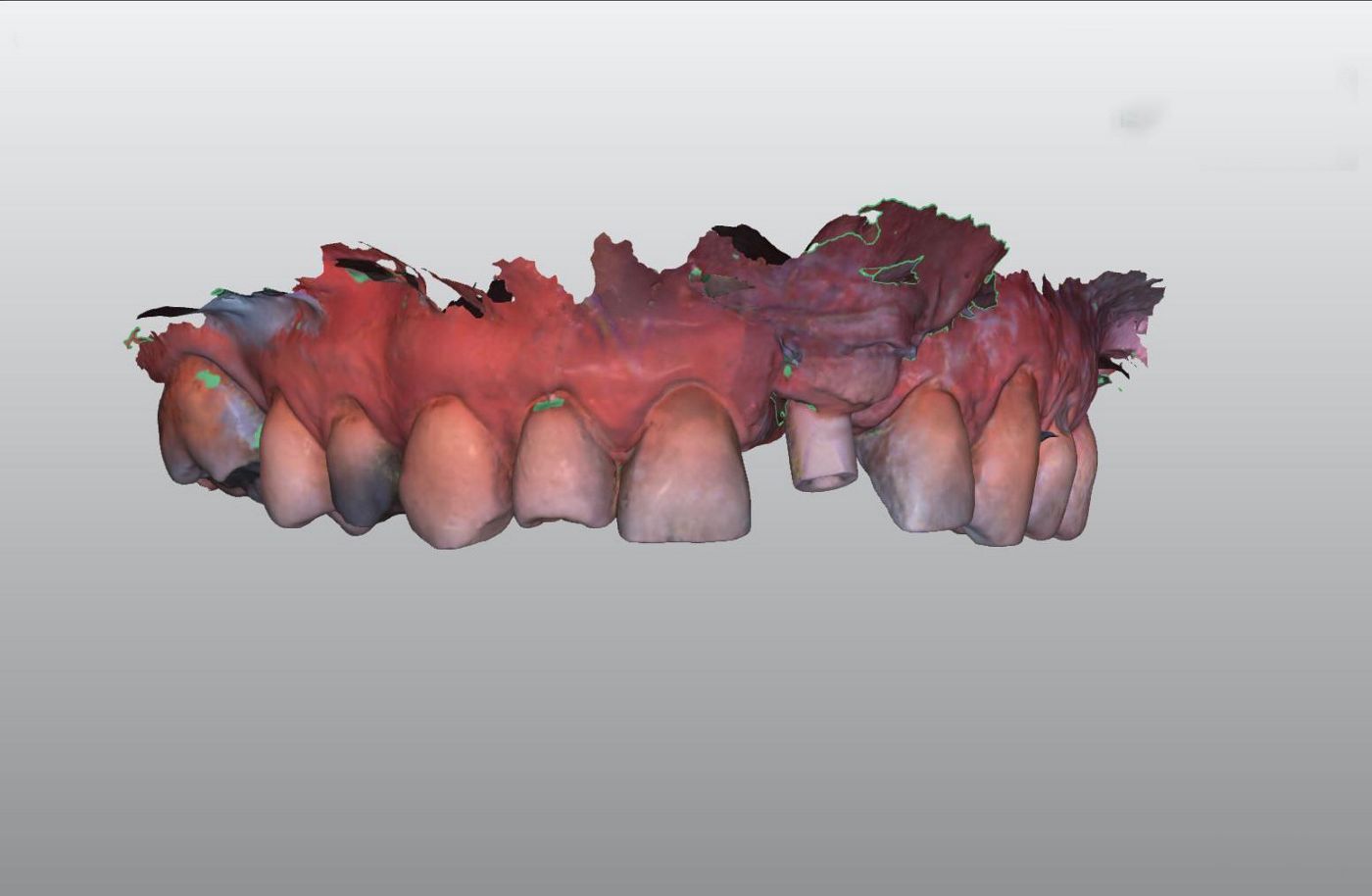

An intraoral impression of the initial clinical situation was taken using the Straumann® Virtuo Vivo™ intraoral scanner (Fig. 4).

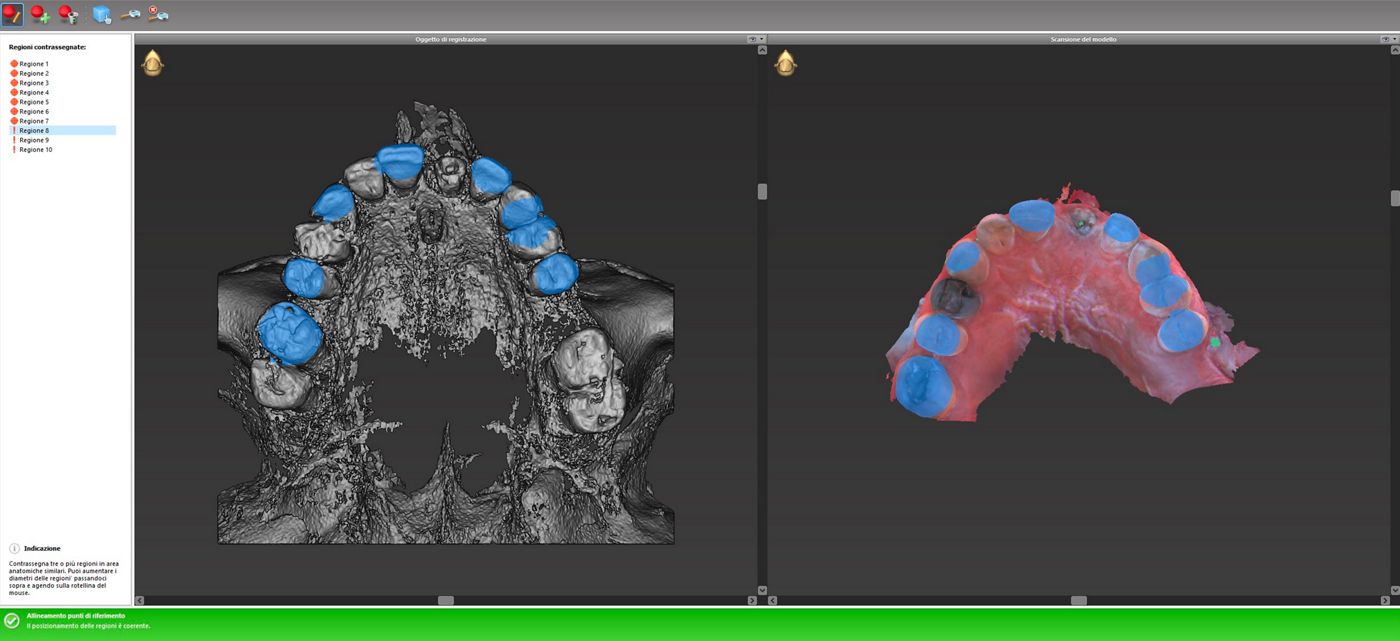

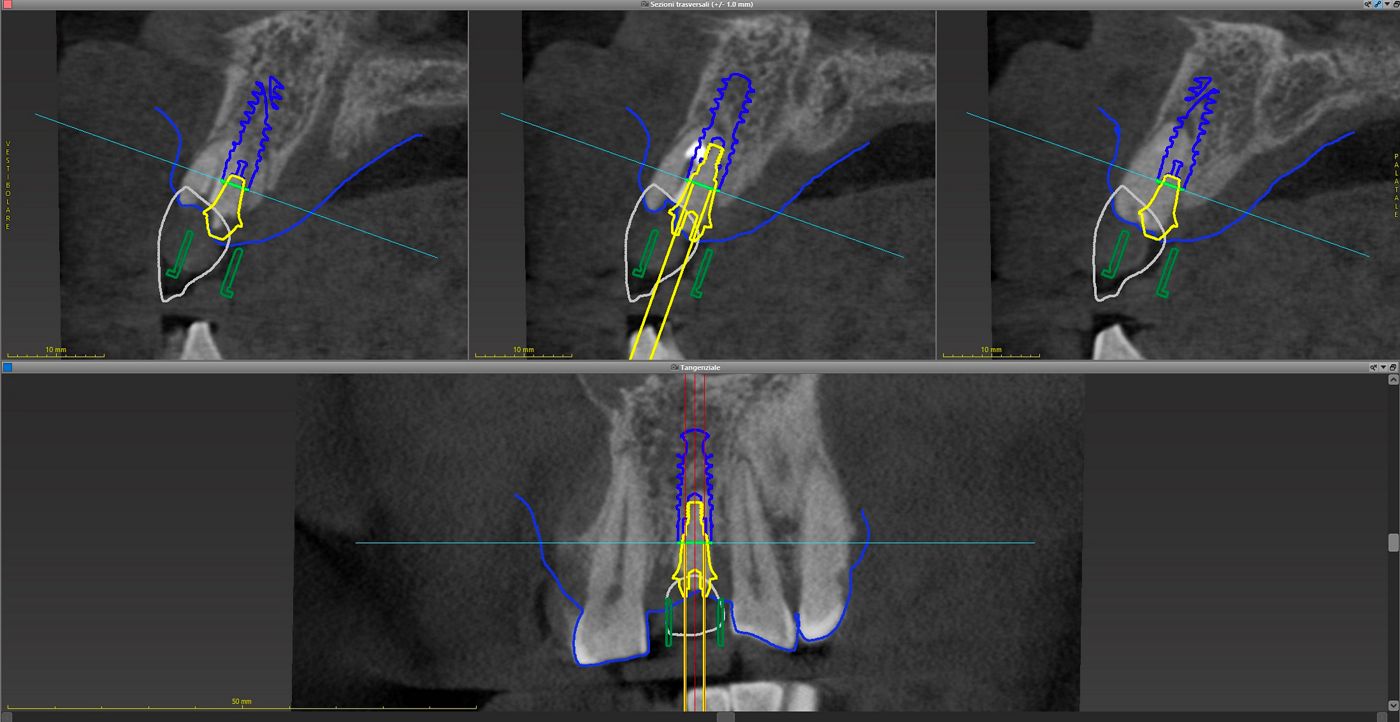

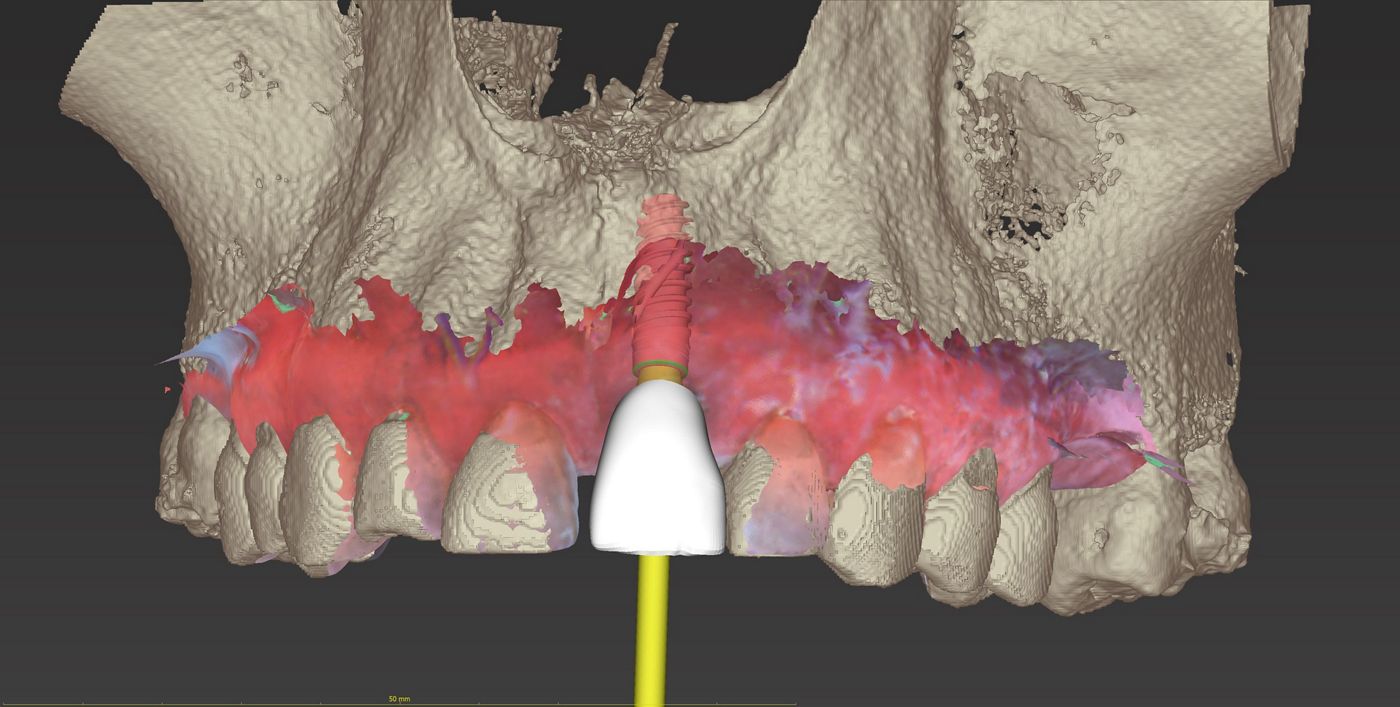

The CBCT DICOM files were imported into the coDiagnostiX® Dental Wings planning software and were created through segmentation to eliminate CBCT data artefacts and obtain a 3D conversion of the bone tissues (Fig. 5).

The PLY file obtained by the initial scan with Straumann® Virtuo Vivo™ imported the information concerning soft tissues and dental surfaces. Moreover, another STL file was created during the prosthetic planning.

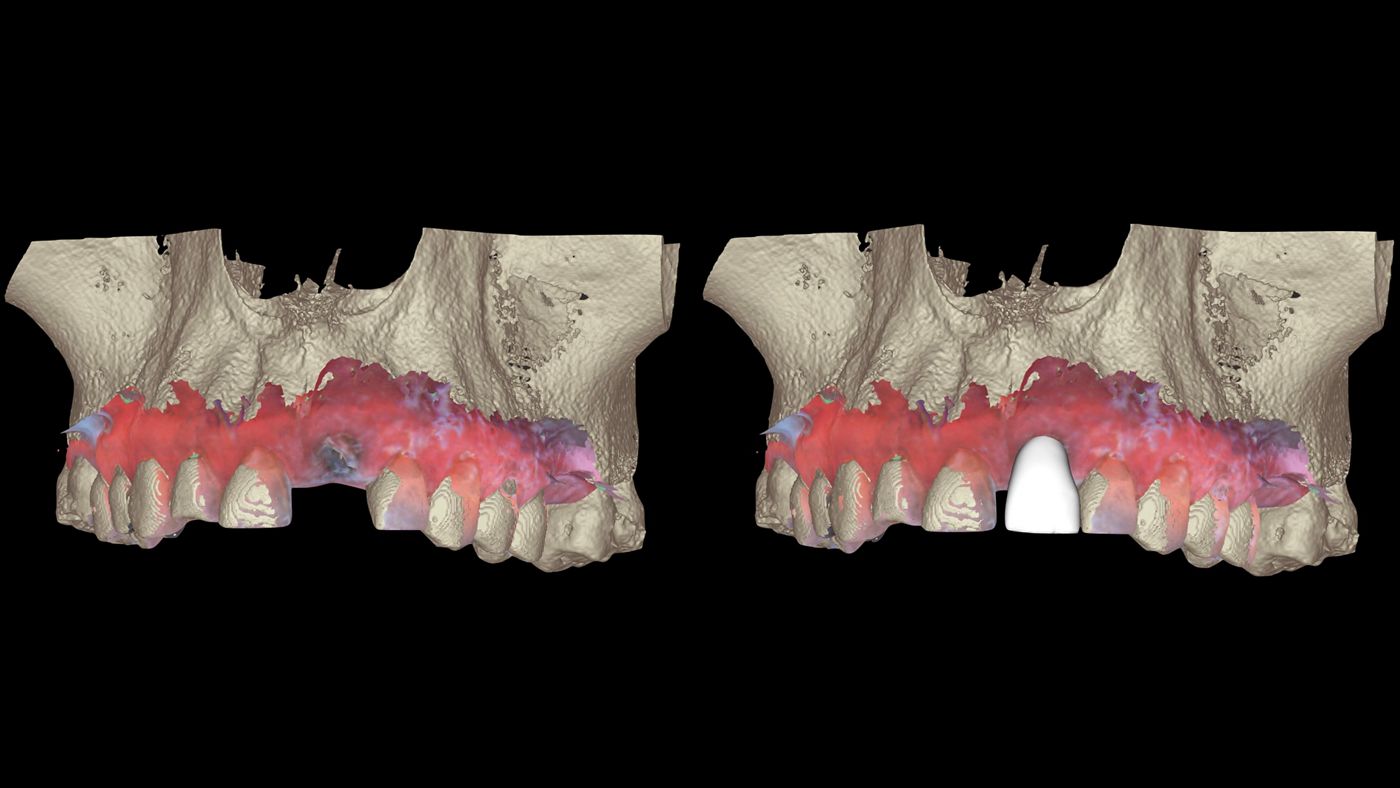

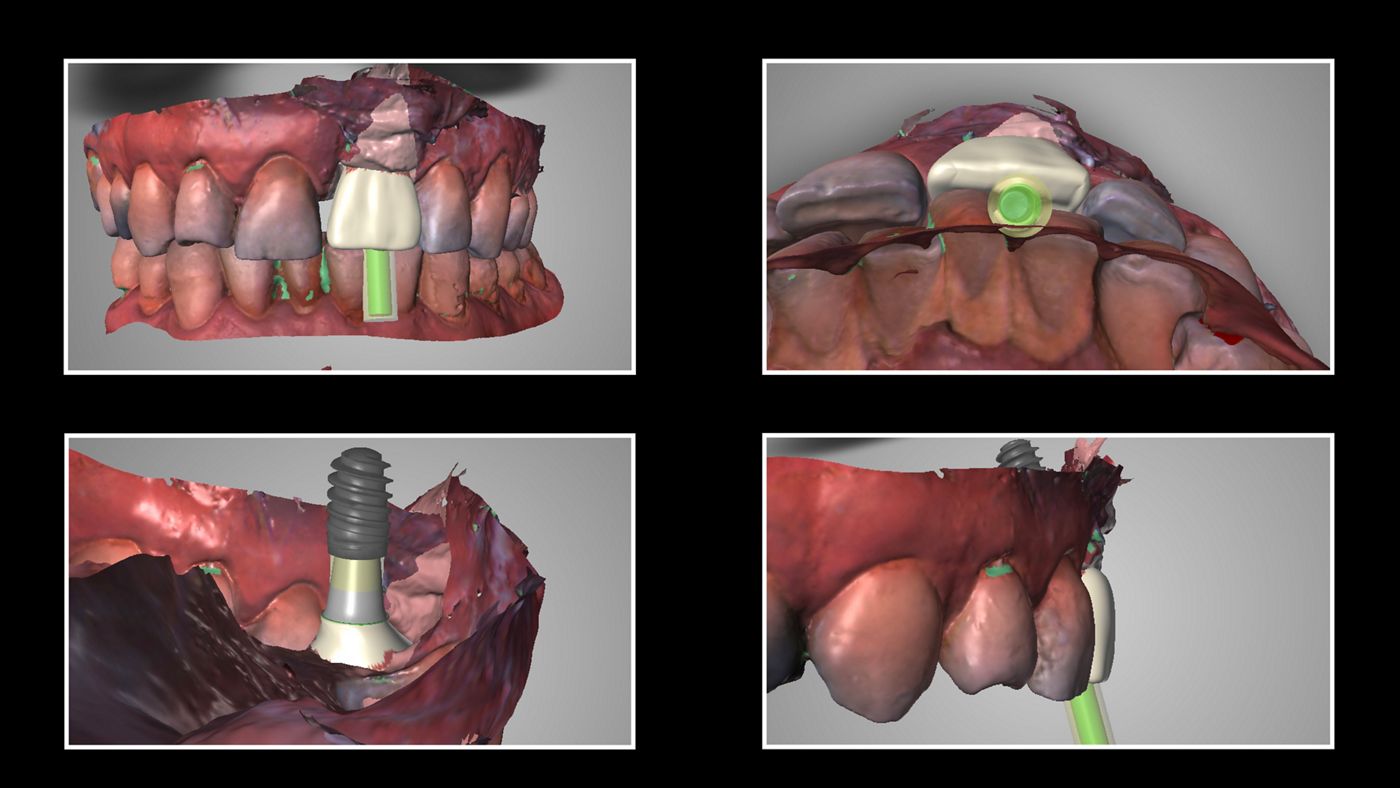

Afterwards, both files are matched by the alignment or superimposition of the two 3D objects (between a segmentation and one STL file, or between two STL files) having in common some regions of interest (ROI). When the areas to be matched on both files are selected, the software automatically determines the matching (Fig. 6). As a result, we obtain images of bones, teeth, mucous membranes and wax that can be perfectly superimposed on one another (Fig. 7).

The ideal implant position can be planned digitally in line with the prosthetic solution that is most suitable for the surgical plan, including predicting the related selection of the most appropriate abutments (Fig. 8).

Following a prosthetic-driven planning strategy, and taking into consideration the bone volume, we planned to insert a Straumann® BLX Roxolid® SLActive® implant 3.75 mm in diameter and 12 mm long (Fig. 9).

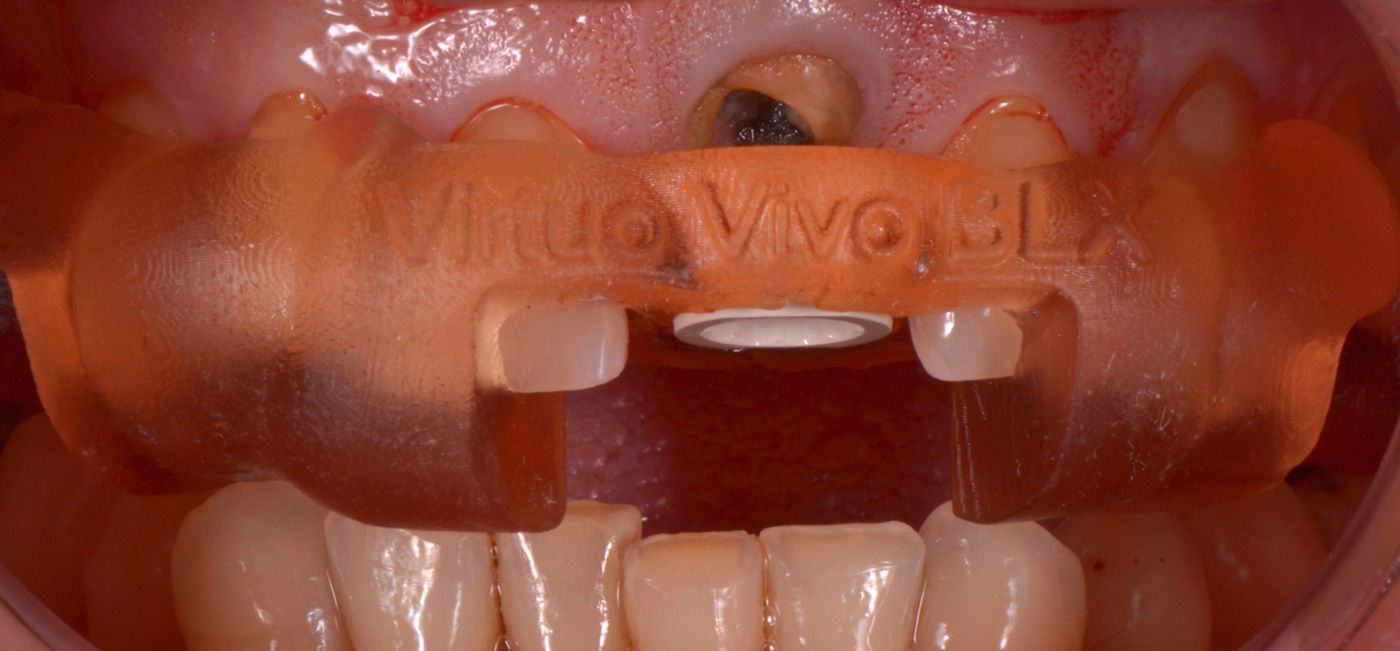

Once the planning was completed, the surgical guide was designed and the corresponding information was sent to the Magma Center lab (Castellammare di Stabia, Italy), where the guide was 3D-printed with a Straumann® CARES® P40 printer (Fig. 10).

These guides are created according to the LPD print technology and, when placed, they seem to fit in a very satisfying way, especially in the case of tooth-supported surgical templates1.

Surgical procedure

The template was placed and proved to be very reliable, precise and stable (Fig. 11).

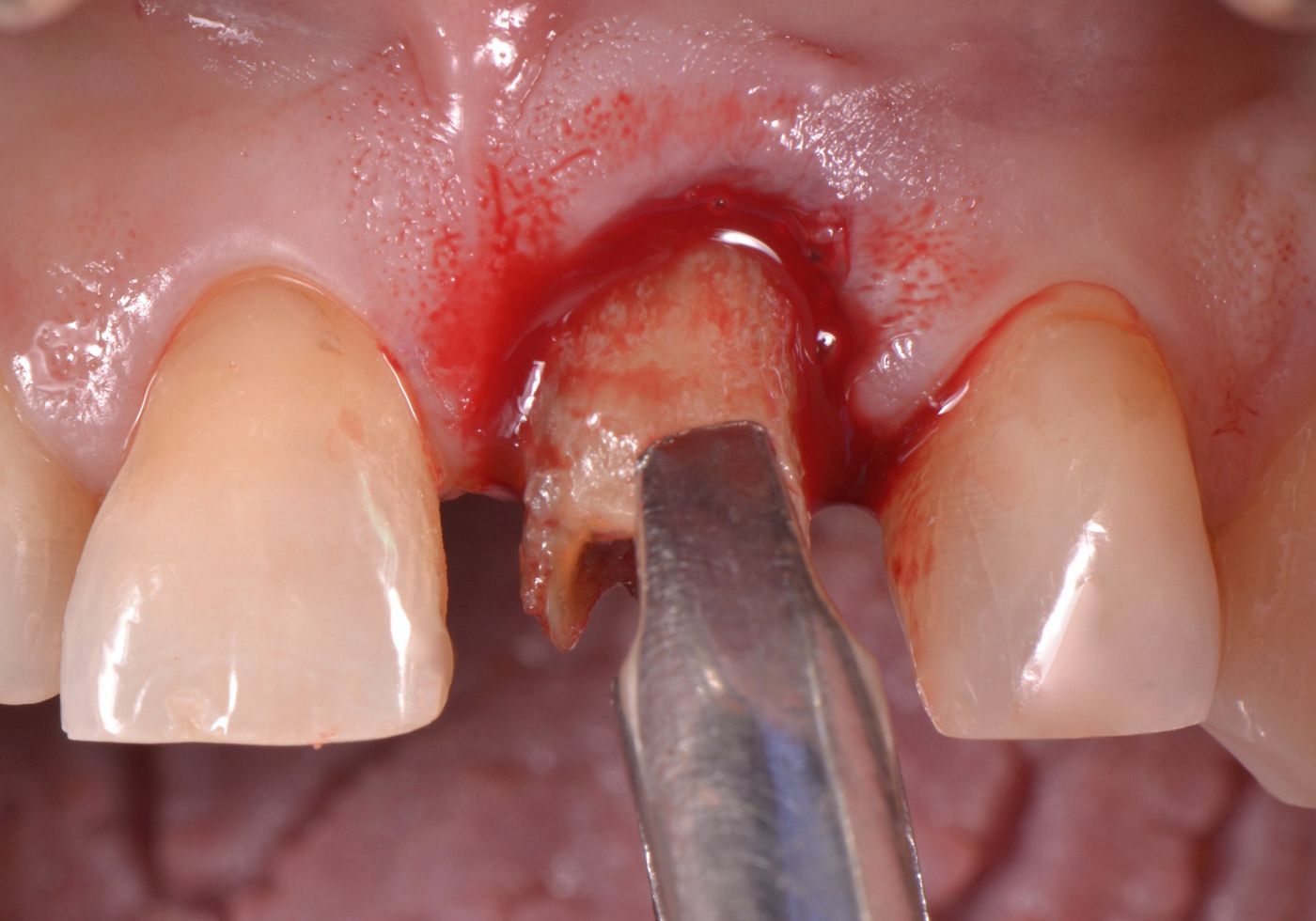

Following the application of local anesthesia, tooth #21 was extracted atraumatically (Fig. 12).

According to the specific BLX surgical protocol, the presence of soft bone allows us to use the Ø 2.2 mm Velodrill™ pilot drill and the Ø 2.8 mm Velodrill™ for the implant bed preparation with abundant irrigation with saline solution (Figs. 13,14).

The surgery was carried out by flapless procedures, following the standard phases of computer-guided surgery. The implant was placed using a specific mounter through the sleeve in an accurately chosen position (Figs. 15,16).

We obtained optimal primary stability and ISQ, and were thus able to proceed with the immediate loading (Fig. 17).

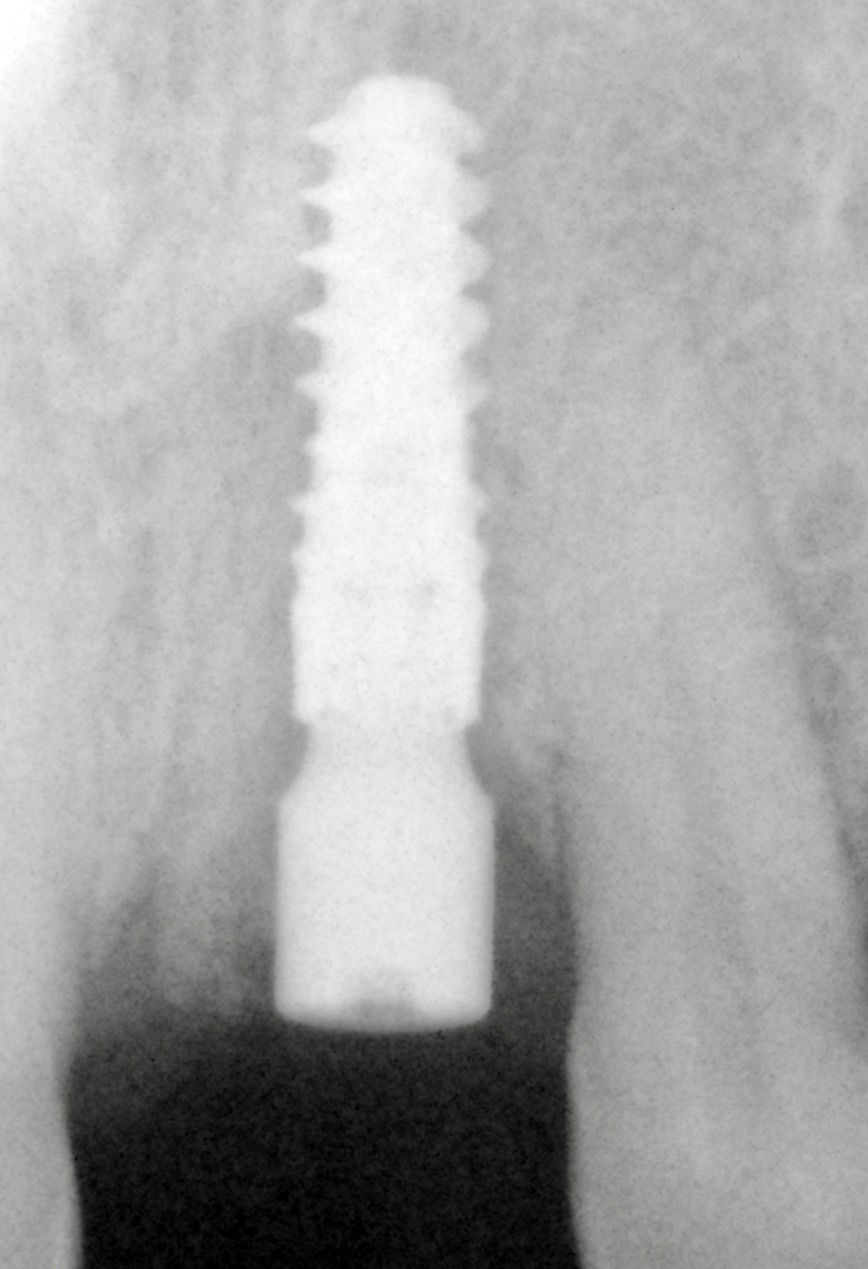

The follow-up radiography showed the excellent precision obtained in implant positioning, which faithfully reproduced in the patient’s mouth what has been accurately planned on the computer (Fig. 18).

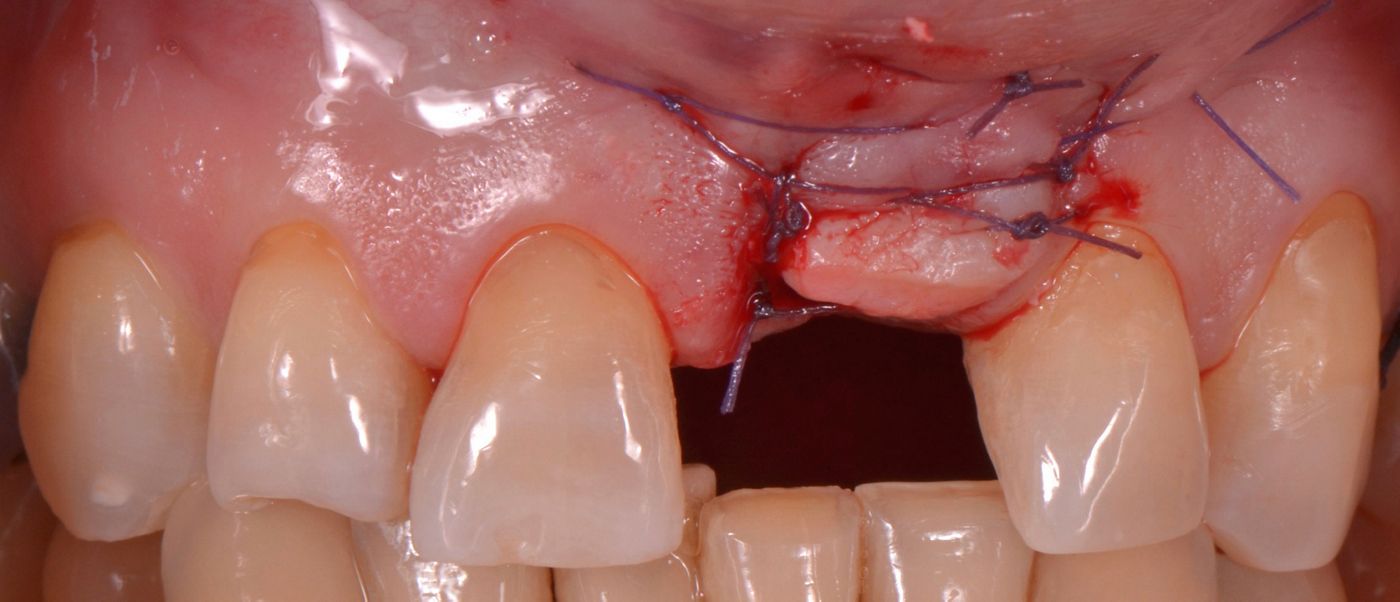

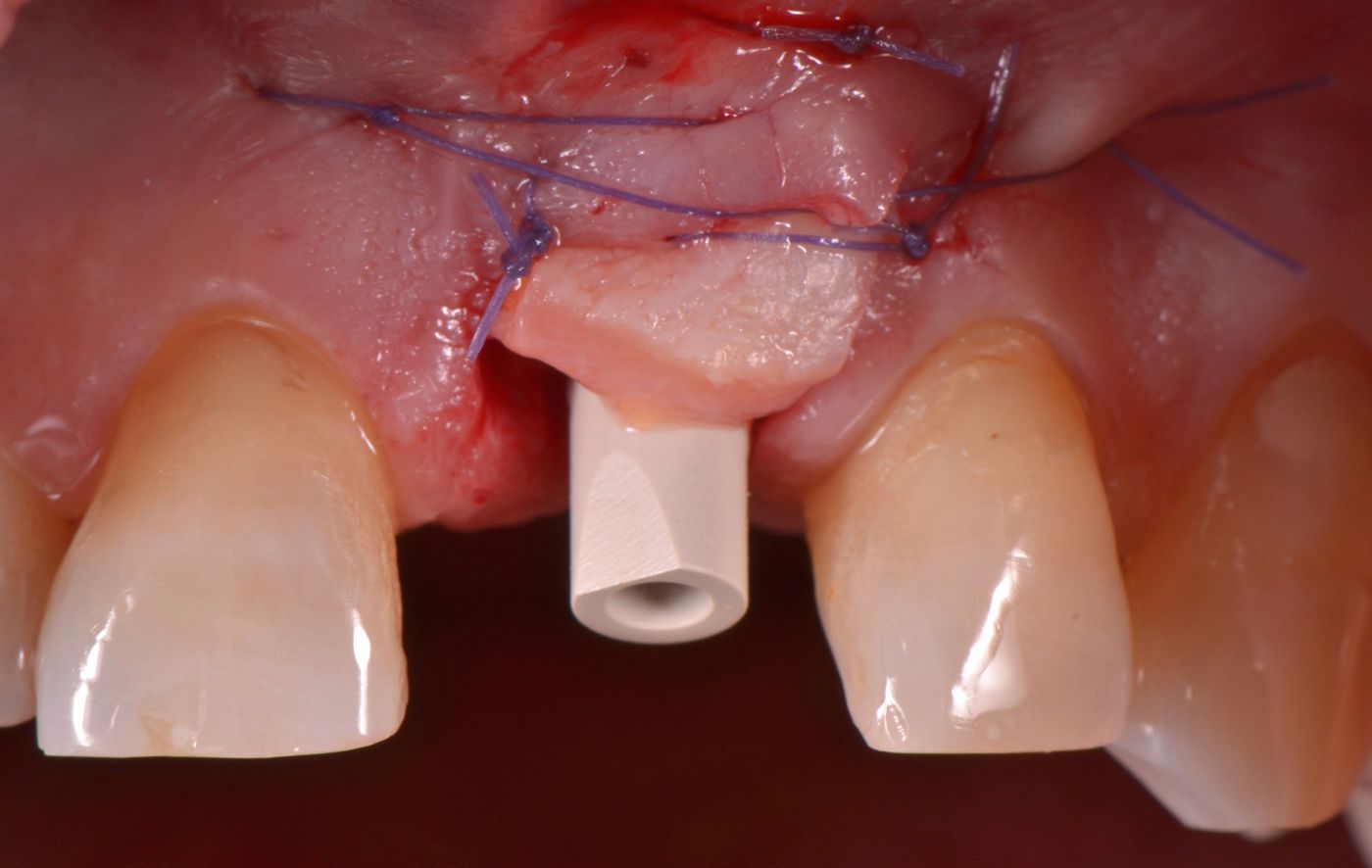

Finally, an epithelium-connective graft was taken from the palate in order to use an envelope technique to optimize the soft tissue profile and act as a vestibular closure and support the bone-implant gap that was filled with cerabone® bone substitute (Fig. 19,20).

Prosthetic procedure

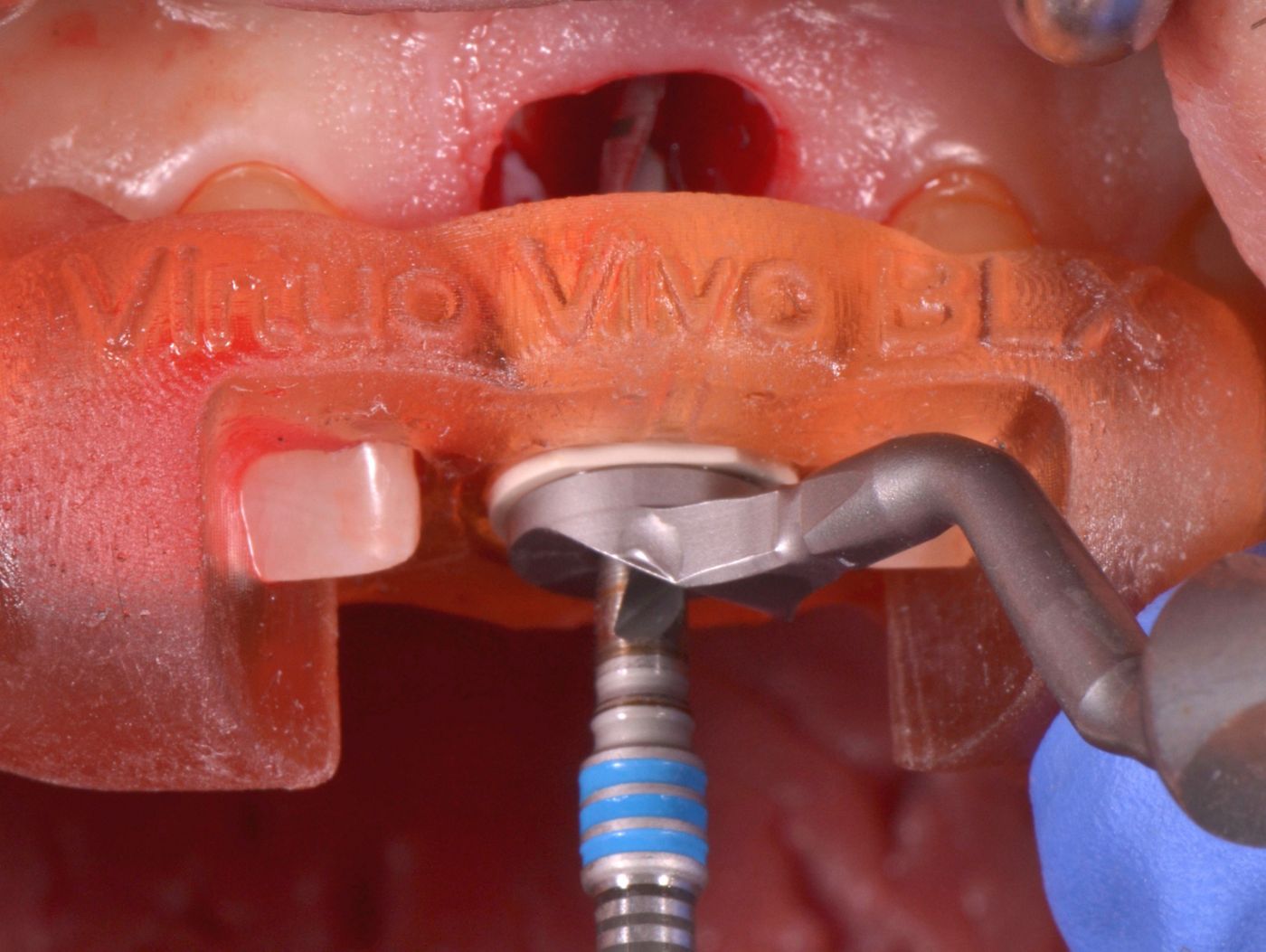

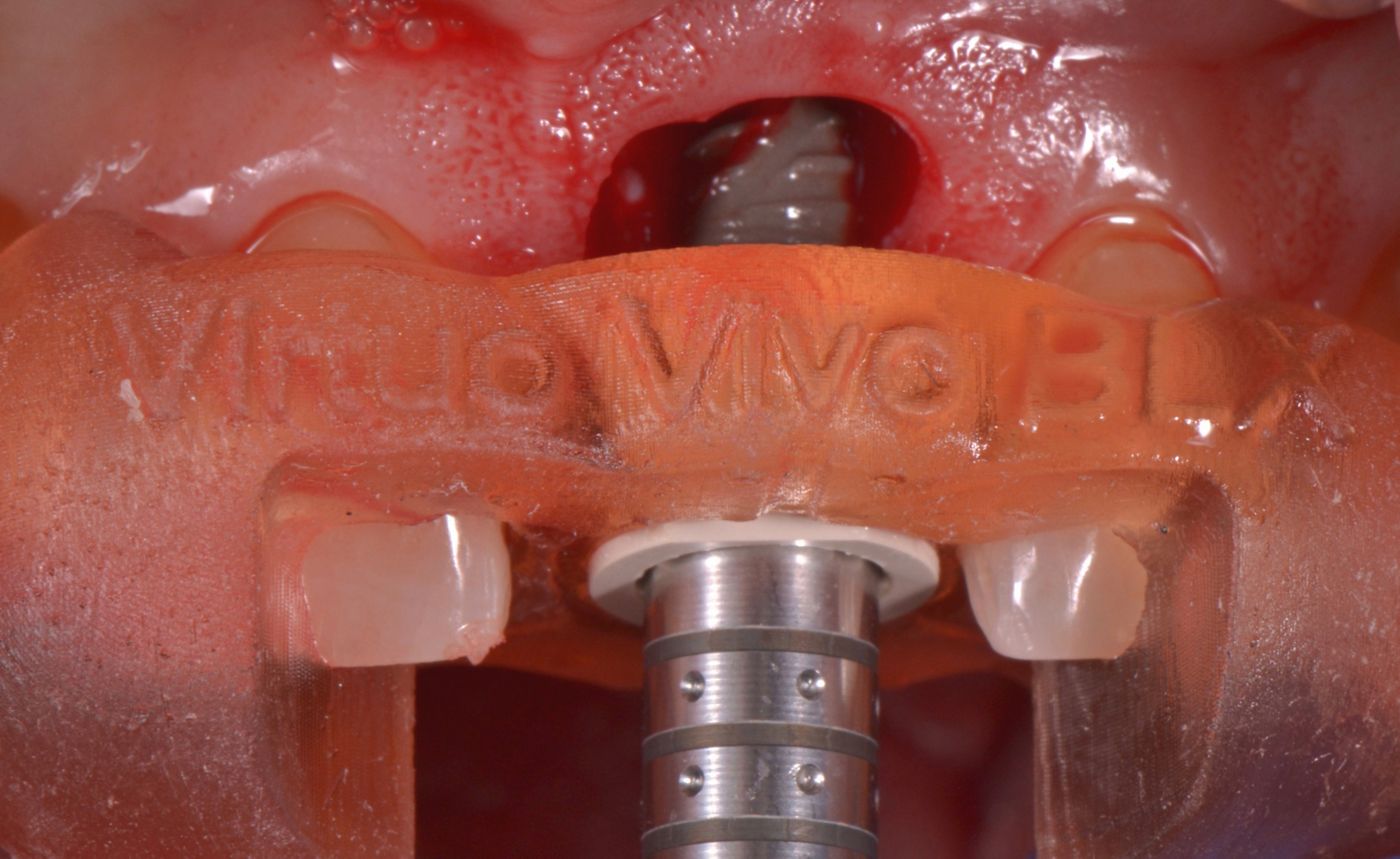

The Virtuo Vivo™ scanner allowed us to take a digital impression of the implant position in order to create a temporary crown using a Variobase® abutment (Fig. 21).

The resulting PLY scan file was sent to the laboratory through CARES® Connect to create the temporary prosthetic crown (Fig. 22).

CAD Straumann CARES® Visual software was used to adjust the temporary crown, making sure that no contacts occurred in centric and protrusive movements (Fig. 23,24).

The CAD was drilled in a PMMA Straumann® Temp Multilayer and glued onto a Variobase® abutment with 3M™ RelyX™ Unicem II cement (Fig. 25).

The temporary crown was screwed to 15 N (Fig. 26).

The temporary restoration was immediately adapted from an esthetic and functional point of view and did not require any changes thanks to the accurate digital planning (Fig. 27).

The scheduled one-month follow-up showed good soft tissue healing (Fig. 28).

Treatment outcomes

The fully digital workflow reduces chair-time and speeds up patient turnover, guaranteeing immediate provisionalization, reduced patient discomfort and immediate soft tissue conditioning. The accurate analysis of the case and treatment planning using all the digital tools at our disposal allowed us to reduce the possibility of mistakes and have a very predictable clinical outcome. Straumann® BLX implant is the perfect solution for the positioning and immediate loading of the implant itself, thanks to its anatomic design, TorcFit™ connection, surface and material.

We would like to thank Laboratorio Magma Center of Castellamare di Stabia for helping with the digital planning and the prosthetic restoration.