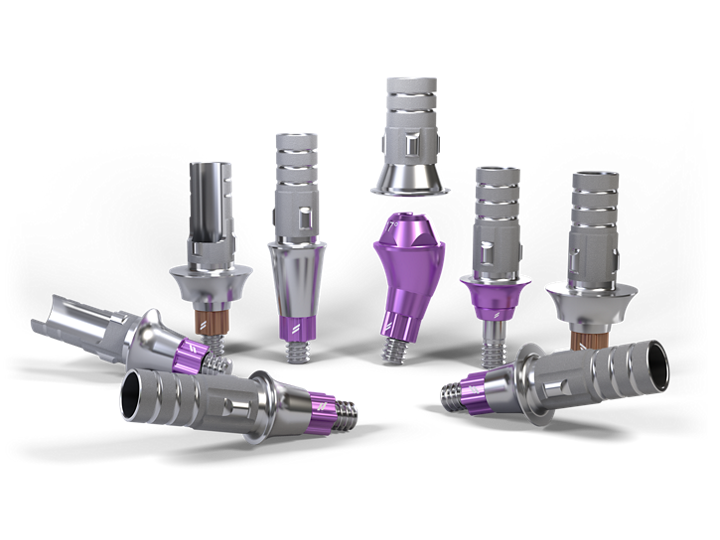

Discover the confidence that comes with a system trusted by over 95,000 dental professionals worldwide. The Straumann® Variobase® XC portfolio for the Straumann iEXCEL™ Performance System empowers both dental technicians and restorative dentists to deliver a tailored solution for each unique case with unrivaled flexibility and precision.

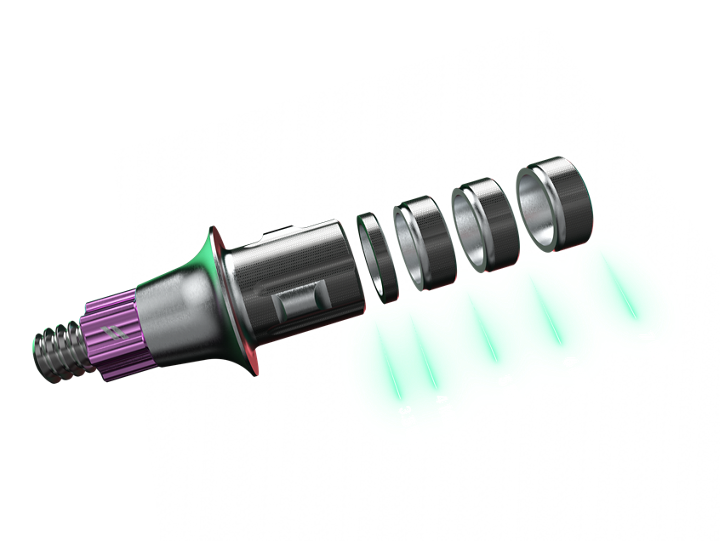

Deliver fit, structural integrity and retention you can rely on with Straumann® Variobase® XC and its original Straumann implant-abutment connection. The next generation builds on the clinically proven performance of its predecessor, with enhanced abutment-crown bonding strength designed to reduce the risk of debonding.

Straumann® Variobase® XC helps you achieve uncompromised esthetics with ease from start to finish. Streamline ordering with the Straumann® TorcFit™ connection and customization with the versatile 7 mm high chimney. Skip sandblasting at the end thanks to the retention of the patent-pending laser surface.

Whether for screw-retained or cement-retained, digital or conventional workflows, the comprehensive and streamlined Straumann® Variobase® XC portfolio enables you to offer customized restorations with ease, even in challenging cases.

Customize with ease

The Straumann® Variobase® XC abutment features a 7 mm tall post that can be used at full height or shortened as needed to suit the clinical situation. Clearly defined machined grooves indicate recommended cut levels, allowing for precise height customization. This provides greater support for taller crowns while offering the flexibility to reduce the abutment height when necessary.

Design the restoration digitally using your preferred CAD software with library files that match the available abutment heights.

Enhanced bonding for a sure fit

We roughen the abutment surface with a proprietary laser treatment, eliminating the step of sandblasting and helping you to avoid the known risks of the process:

- Altering tolerances or structural components

- Reducing structural strength

- Potential contamination

Enjoy the peace of mind that comes with Straumann® Variobase® XC, knowing Straumannʼs Swiss engineering and precision manufacturing is completely intact.

Portfolio overview

Key indications |

Single-unit | Multi-unit | Full-arch |

| Implant systems | Straumann iEXCEL™ Implant System ( BLX | TLX | BLC | TLC ) |

Fixation |

Cement-retained | Screw-retained |

Material |

TAN |

Workflow |

Traditional | Digital |

Prosthetic connections |

RB/WB, WB, NT, RT, WT |

STraumann® Variobase® XC

for crown

- Strong retention negating need to sandblast

- 7mm high chimney

- Integrated cutting grooves for easy customization

Straumann® Variobase® XC

for crown AS

- Screw channel angulation up to 25°

- Uncompromised esthetics in anterior region

- Correct channel position to improve access and functionality in the posterior region

Straumann® Variobase® XC

for bridge/bar

- Strong retention negating need to sandblast

- Comprehensive range of gingiva heights

- Straight and angulated options

- Integrated cutting grooves for easy customization

Straumann® Variobase® XC

Coping for screw-retained abutments

- Strong retention negating need to sandblast

- Straight and angulated options

- 7mm high chimney

- Integrated cutting grooves for easy customization

Consistent emergence profiles™

Optimize the soft tissue management process with the uniform emergence profile of the Straumann iEXCEL™ bone level abutments.

Straumann® Variobase® XC Digital Workflow

In-house control

Capture the scanbody (bone or tissue level) or healing abutment (bone level).

Straumann® Scanbodies

Straumann® Anatomic Healing Abutments XC

Design the prosthesis with the preferred CAD software using Straumann® Variobase® XC libraries.

CADCAM Libraries

Mill the prosthesis designed in the CAD software.

Choose the appropriate repositional analog, print a model, finalize the prosthesis, and send to clinician.

Outsourcing flexibility

Submit your scan to Straumann UN!Q™ via Straumann AXS™

OR

Ship the model and outsource the scan to Straumann UN!Q™.

Design the prosthesis with the preferred CAD software using Straumann® Variobase® XC libraries.

OR

Outsource the design to Straumann UN!Q™ via Straumann AXS™.

Outsource manufacturing to Straumann UN!Q™. Track your case 24 / 7 on Straumann AXS™.

Receive the case from Straumann UN!Q™, finalize the prosthesis and send to clinician.

Featured stories on youTooth

Brochures and videos

Looking for additional information? Visit the Resource Center.

Looking for CADCAM files? Visit the CADCAM Libraries.