Initial situation

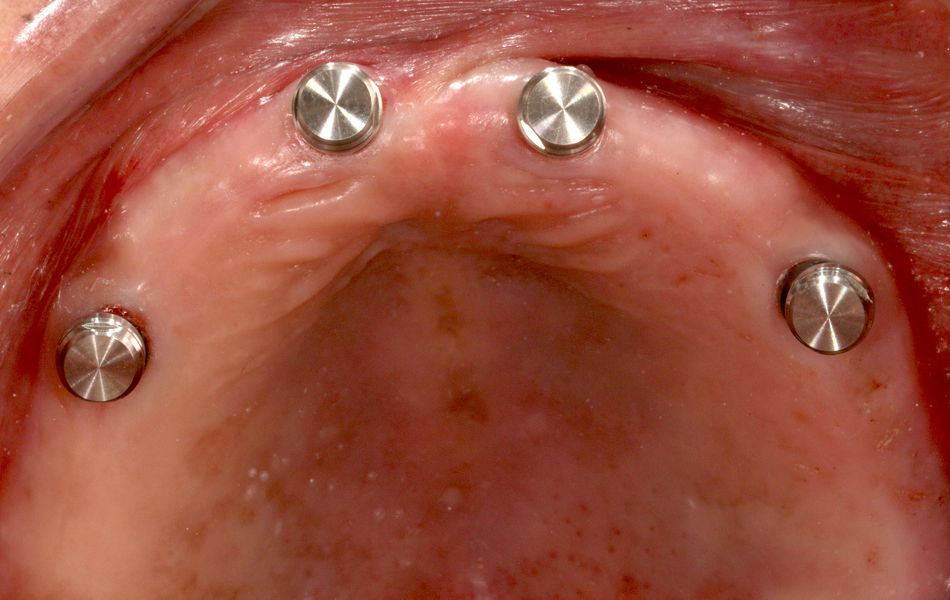

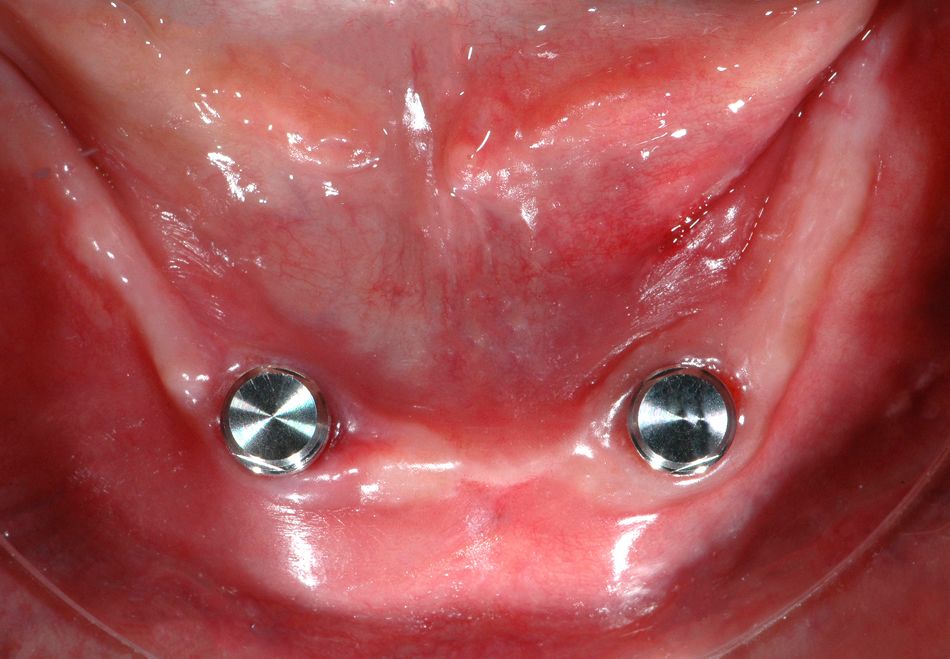

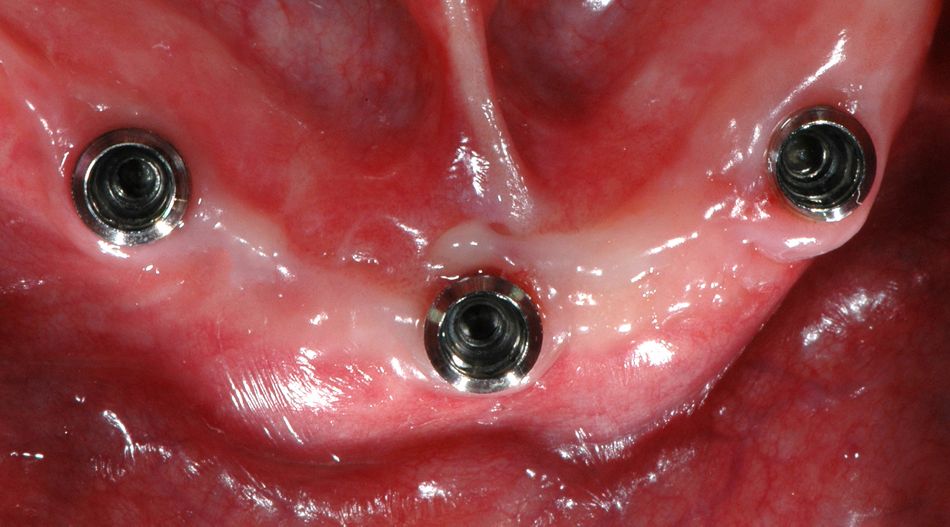

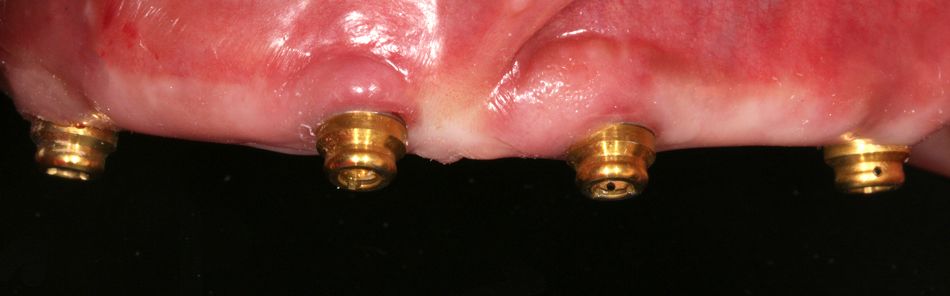

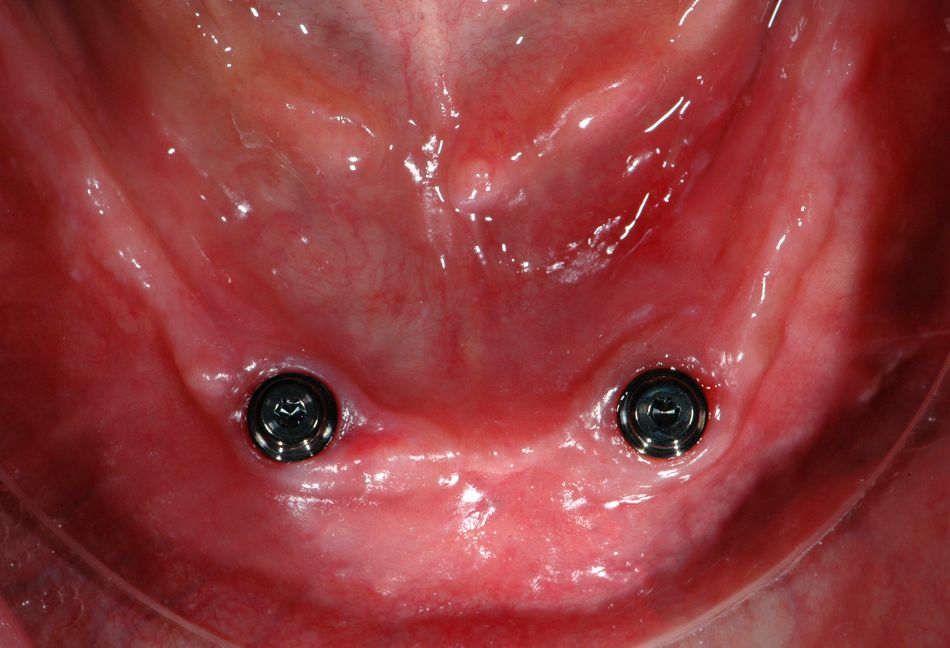

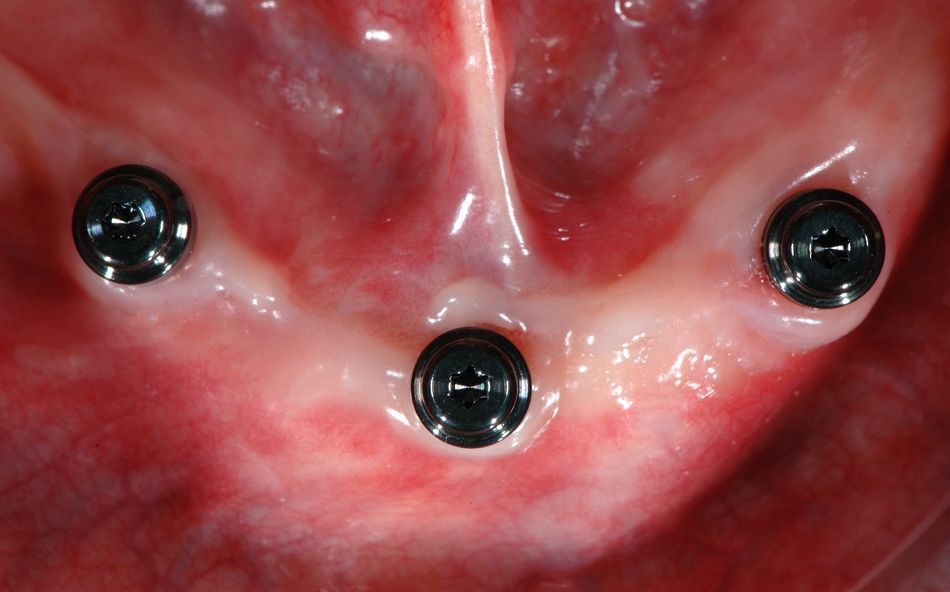

Three healthy edentulous patients presented with osseointegrated implants. Patient A is a 63-year-old male with four implants in the maxilla, (Fig 1) patient B is a 74-year-old female with two implants in the mandible (Fig 2) and patient C is a 59-year-old male with three implants in the mandible. (Fig 3)

Treatment planning

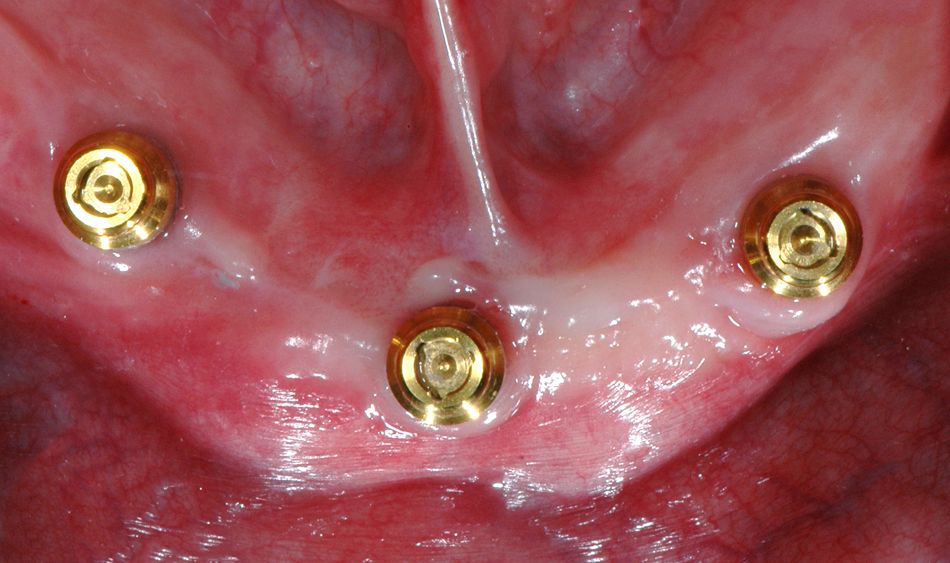

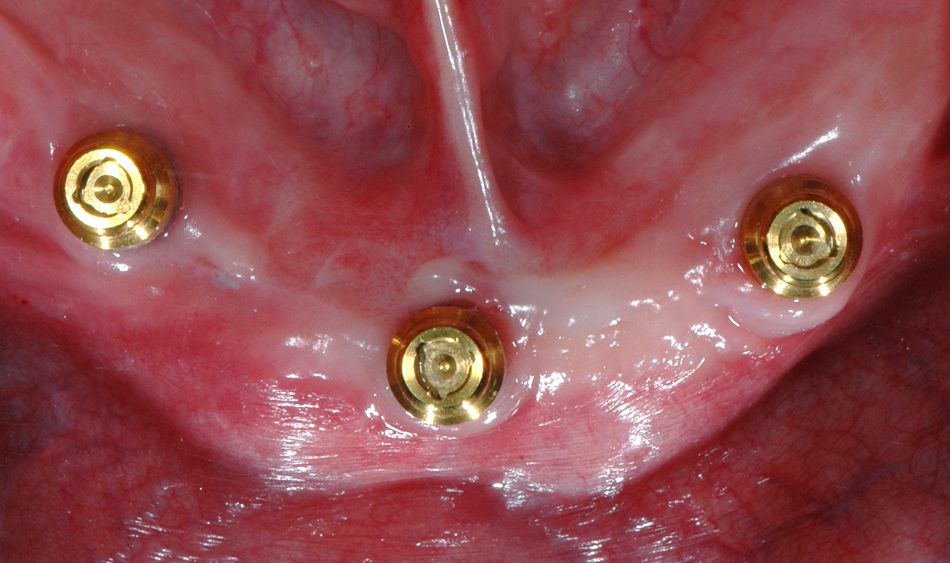

All patients had used an overdenture for more than 5 years supported by Locator® abutments. We found that the common clinical characteristic between these three patients was that they have had to replace their nylon matrices more than once every 6 months. Despite having the same characteristics, the main complaint of each patient was totally different. Patient A had a hard time removing his overdenture, (Fig 4) patient B wanted her overdenture to have stronger retention and esthetic translucency (Fig 5) and patient C wanted the retention matrices in his overdenture to last longer. (Fig 6)

Prosthetic procedure

Patient A: had four Straumann® Bone Level implants in the maxilla. We aimed to make his overdenture easier to remove. Because the abutments were divergent by 13°, (Fig 7, 8) we decided to change the abutments in order to reduce the divergence between the implants with the use of Novaloc®, with a combination of straight 0° abutments in the anterior implants and angled 15° type A CrossFit® connection abutments in the posterior implants. (Fig 9, 10) This way we were able to reduce the stress, force and friction on the matrices, enabling the patient to remove his overdenture more easily.

Patient B: had two Straumann® Tissue Level implants in the mandible. To give her stronger retention we decided to use Novaloc® straight 0° abutments activated with extra-strong matrices made of PEEK, a high-performance polymer stable against almost all organic and inorganic chemicals with excellent biocompatibility. The matrix can handle insertions with up to +/- 40° divergence. (Fig 11) To improve the esthetic translucency of the housings through the overdenture, we used the new neutral color PEEK housings instead of titanium, which produce better esthetic results in areas where the base of the overdenture has thinned. (Fig 12, 13, 14)

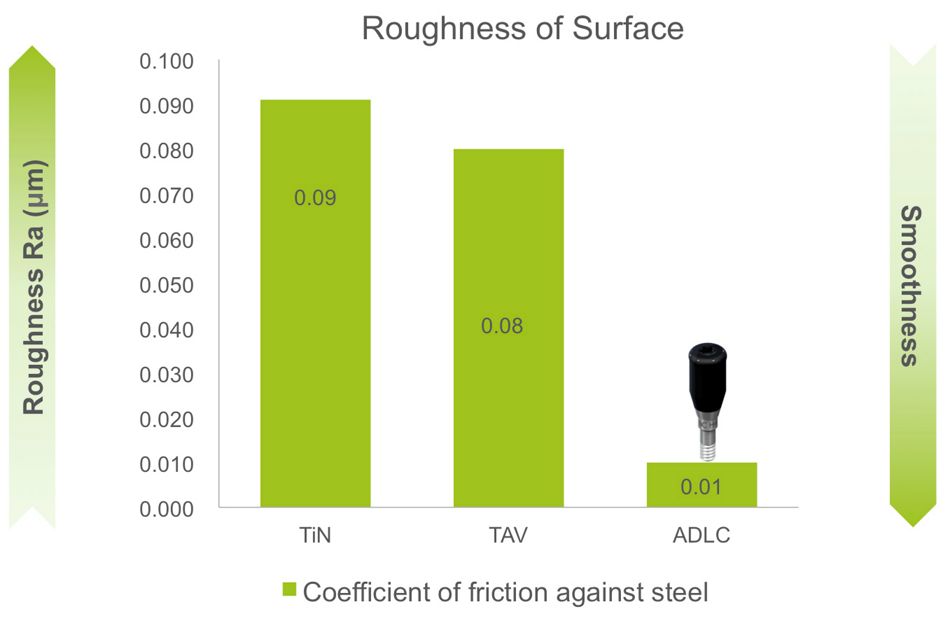

Patient C: had three Straumann® Tissue Level implants in the mandible. To improve the durability of the retention matrices, we chose Novaloc® (Fig 15) instead of Locator® (Fig 16) abutments. Because Novaloc® has an amorphous diamond-like carbon (ADLC) coating, friction is minimized, even without lubrication. The ADLC coating gives a very smooth surface, with low friction and excellent protection against abrasion. A lower coefficient of friction (roughness) means a smoother result, providing us with a less abrasive abutment which lasts longer and maintains more than 85% of the retention properties of the PEEK matrices after 10,000 cycles (~10 years of use). (Fig 17)

Treatment outcome

The chief complaint of the three patients was addressed. In patient A, Novaloc® clinically corrected the divergence between the implants and improved the insertion of the overdenture. In patient B, it increased the retention strength with the PEEK matrices and improved esthetic translucency with the neutral color PEEK housings. And in patient C, it improved the durability of the retention matrices, reducing the need to change them and resulting in a favorable long-term prognosis and greater comfort. One of the three final prostheses. (Fig 18, 19)