The “Learn in a Box” concept

We want to give our customers the flexibility to train with our products whenever and wherever they want. To this end, they can order a preconfigured and product-specific box that contains all the components and instructions for a hands-on exercise. Providing this box in a new and eco-friendly material was a unique opportunity to make a sustainable impact and add value to the company’s efforts to safeguard the environment.

“This has produced a real wow effect in the customers. The feedback from Europe and the USA has been very positive.”

Marcel Kunz, Head of Global Packaging at Straumann HQ in Basel, Switzerland

Grass cardboard at Straumann

In 2020, Straumann introduced a box made from grass cardboard for its “Learn in a Box” concept. This cardboard contains up to 25 percent of grass fibers and is processed by our partner, the printing company Gantenbein (part of the Bloch Group) in Arlesheim just outside Basel, where Straumann is based. The grass fibers are made from 100% virgin fibers and contain no allergens. The patented process integrated in the product used by Straumann involves purely mechanical processing with a small amount of lignin. The energy consumed is reduced by 97% compared to conventional methods, and the process requires very little water and no chemicals. The raw material starts with hay harvested from regional compensation areas within a radius of 100 kilometers, and the CO2 reduction can be as high as 75%.

Grass makes a difference

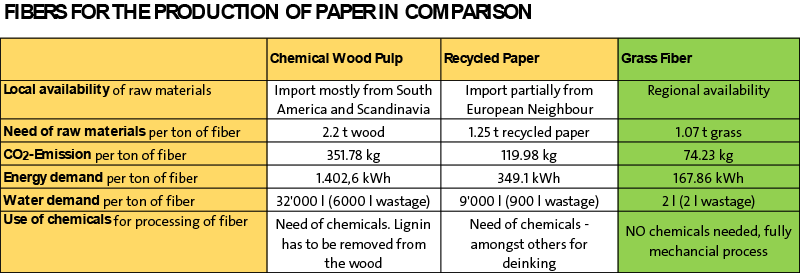

As an industry and manufacturer, we have to train dentists how to use our products. But at the same time, we are mindful of the resources used and outputs from our operations and production processes. As we delved deeper into the topic, we were impressed by the huge difference the grass paper makes in terms of the required quantities of water and CO2.

Marcel Kunz (Head of Global Packaging at Straumann HQ in Basel, left in the photo) examines the new grass cardboard box with Markus Eggler.

Want to stay up to date?

youTooth.com is THE PLACE TO BE IN DENTISTRY – subscribe now and receive our monthly newsletter on top hot topics from the world of modern dentistry.

Ecologically and economically beneficial

Despite decades of increasing digitization, paper is still irreplaceable, and the demand is growing worldwide. But conventional paper products harm the environment and produce CO2 as a by-product. Grass paper, grass cardboard and grass packaging offer a genuine alternative to traditional paper manufacture with cellulose. Grass paper possesses all the properties needed for paper production. As an addition to cellulose, grass / hay serves as a substitute raw material that can be used by industry in an ecologically and economically beneficial process. Unlike trees, grass grows very quickly and can be harvested several times a year. The short procurement routes also contribute to an improved environmental footprint, with reduced CO2 emissions. In corresponding techniques, the fibers can be processed by purely mechanical methods without the use of chemical additives or water – providing a dual benefit for the environment. Grass paper offers one further advantage: not only can it be recycled as used paper, it can also be composted. The consumer can therefore choose whether to dispose of the packaging via the paper or organic waste bin.

The potential to revolutionize industrial paper manufacture

Compared to conventional cardboard, grass cardboard requires much less energy, water and chemicals.

Source: Creapaper

“Wherever possible, we try to make our own contribution to reducing the waste mountain. Cardboard offers great opportunities here, since it can very easily be disposed of and recycled.”

Marcel Kunz, Head of Global Packaging at Straumann HQ in Basel, Switzerland

Cardboard as secondary packaging

The medical device industry is a highly regulated environment with many rules that define the requirements for a packaging system. The course material gave us the opportunity to be more flexible, so it is the perfect place to try new approaches to packaging and learn how to be more sustainable. Cardboard is suitable as secondary packaging for sterile products – protecting the sterile barrier. The secondary packaging is usually a cardboard box, which also serves as an information carrier. Thanks to its excellent printability, cardboard is also perfectly suitable as protective packaging for non-sterile products.

Following this successful pilot project in ecological packaging, we at Straumann will be investigating new ways of using this innovative material.